30 Years Experience

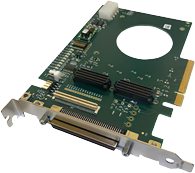

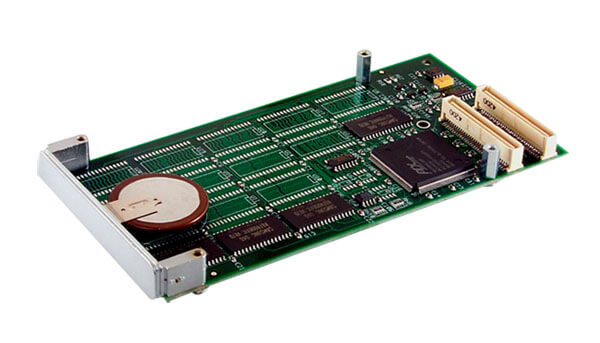

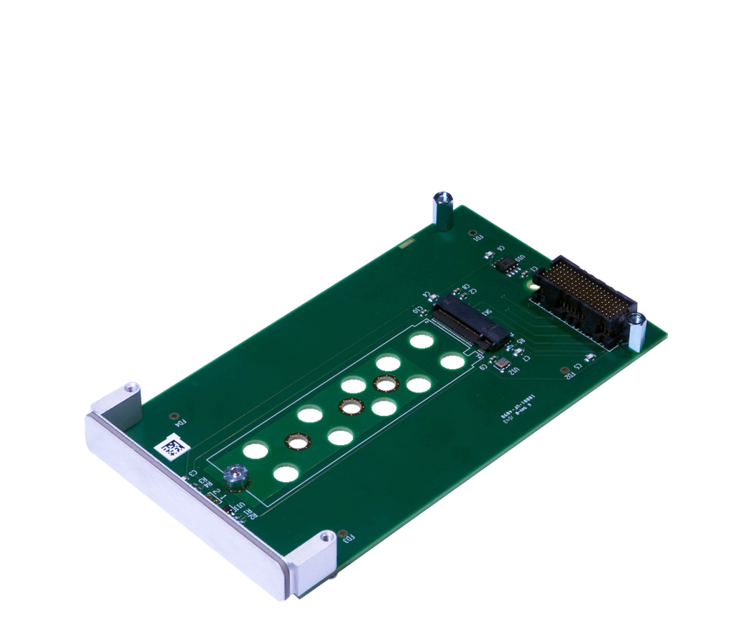

A recognized leader in the board-level solutions industry for exceptional COTS (commercial-off-the-shelf) products, mezzanine cards & engineering design. Technobox, Inc. offers the most extensive range of PMC/XMC boards, carriers and adapters providing asynchronous I/O, digital I/O & memory for OpenVPX, VME, Compact PCI, Serial cPCI and embedded systems. Offering Out-of-the-Box solutions and innovative products at a fair and industry-competitive price for over 30 years.

U.S. Manufactured

Headquarters proudly located in West Berlin, New Jersey, Technobox, Inc. supplies mezzanine card (PMC/XMC) assemblies, as well as associated adapters, carriers and development tools for board deployment and testing. End-user applications address a diverse range of markets including information processing, aerospace/defense, industrial process control and transportation.

Customer Centered

Our talented engineers and production staff offers extensive OEM industry experience with years of component and PCB supplier relationships – providing over 175,00 boards to prominent defense, aerospace and industrial automation clients such as: Boeing, Lockheed Martin and Raytheon. Complete customer satisfaction is critical to our continued success.

Advanced Facility

Top-of-the-line manufacturing plant, featuring Vapor Phase reflow technology. Our facility offers a variety of mezzanine board solutions that service supplemental I/O and storage for embedded systems. Every aspect of production happens in-house. All boards and accessories undergo extensive functionally testing by highly-qualified production specialists and engineers. Designed, assembled, delivered – you request and we respond!

Quality Focused

ISO 9001:2015, VITA and IPC610 certified, our environmentally-controlled facility includes ESD flooring, positive pressurization and an in-house database specially tailored to electronic manufacturing. We handle both leaded and RoHS assembly, as well as conformal-coating and on-site functional product testing.

Why choose

technobox

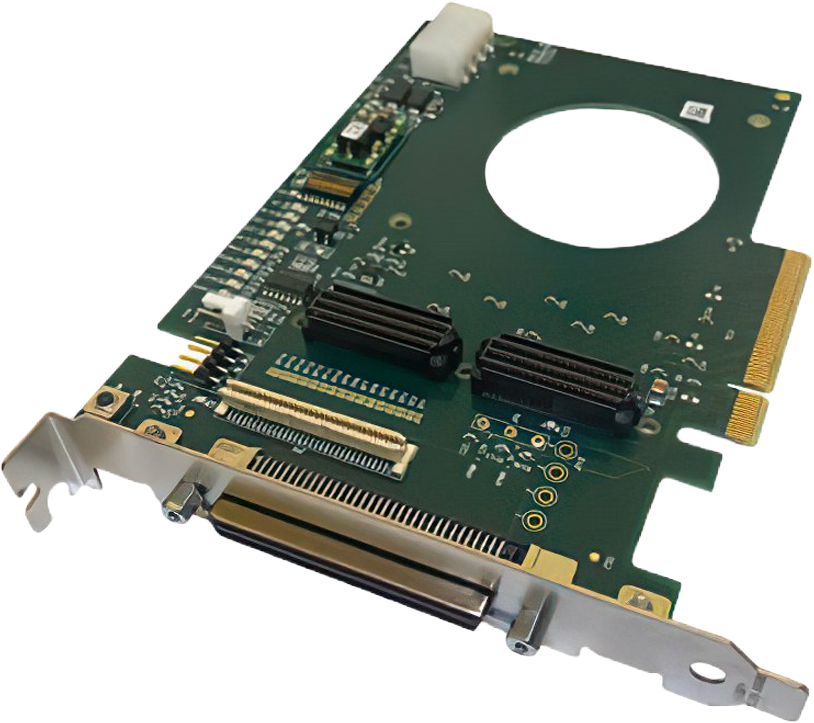

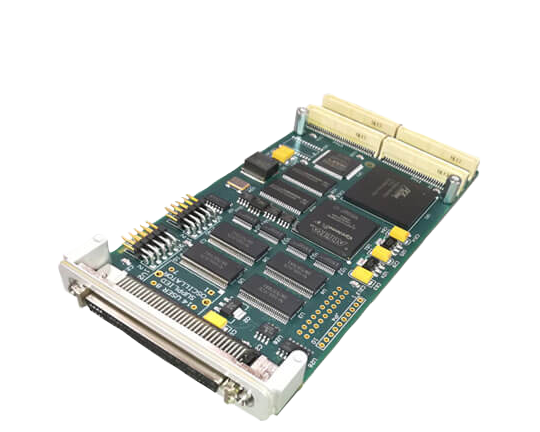

featured products

Many thanks to NJMEP for having

Technobox out to their outstanding

conference to display our product offerings!

They really are Helping New Jersey Manufacture Success!

Technobox, Inc. installs second X30™ Fully Automatic Stencil Cleaner for superior performance

WEST BERLIN, NJ – February 2022 – Technobox, Inc. is pleased to announce the purchase of its second X30™ Fully Automatic Stencil Cleaner. Located in West Berlin, NJ, Technobox’s talented engineers and production staff offer extensive OEM industry experience. The company relied on AAT’s X30 cleaning system for many years, and with its continued growth, decided it was an opportune time to invest in a second machine.

Offering COTS (commercial-off-the-shelf) products, mezzanine cards and engineering design for over 30 years, Technobox manufactures the most extensive range of PMC/XMC cards, carriers and adapters on the market – providing a variety of embedded solutions to clients in the energy, transportation and defense industries. When it comes to cleaning high-value components, the company requires utmost flexibility.

The X30 provides Technobox with maximum chemistry flexibility designed to meet a wide variety of applications. Aqueous, saponification, semi-aqueous, alcohols and hybrid solvents are utilized to remove solder pastes, adhesives and various other residues from boards, stencils or tooling used in the production process.

“The X30 cleaner is a key component of our water-soluble Flux SMT line. It is excellent for low/medium production rates, and cleans our PCB’s, stencils and squeegees in a small footprint with no discharge,” commented Mike Finerty, Senior Electrical Engineer, Technobox, Inc. “Very easy to install, program and maintain, and saves space on the shop floor by combing multiple functions into one machine.”

Senior Engineer, Mike Finerty posing with the X30™ Fully Automatic Stencil Cleaner at the Technobox, Inc. production facility in West Berlin, NJ.

With the X30, users can expect consistent cleaning results from its patented method of rotational spraying – creating zones of constantly changing force that provide superior performance and reliability. A fully automated cleaning system, the X30 does not require product transference between wash, rinse and dry cycles.

Incorporating filtration and a selectable open-loop/closed-loop configuration, the X30 addresses Technobox’s environmental and safety concerns. The cleaner’s automated lift and compact body design easily facilitates load/unload procedure and provides the industries’ smallest footprint. MORE ABOUT TECHNOBOX’S X30™ AUTOMATIC STENCIL CLEANER